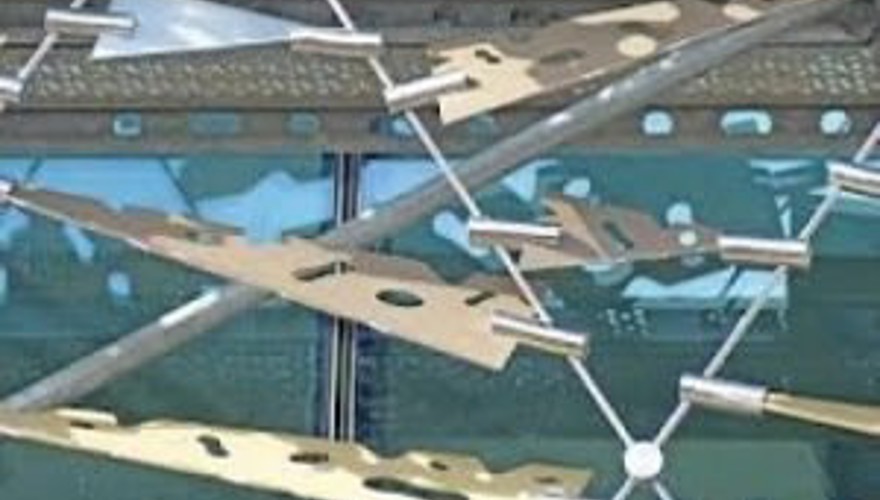

Late in 2012, CNC Machining received the contract to provide Stainless Steel clamps for the architecturally designed facade of the brand new ASB Building on Auckland's waterfront. With a nearing deadline combined with the sheer volume of components required, this was one of CNC Machining's biggest challenges to date.

The main challenge for us was the complex nature of the variations required. Each individual part had up to 7 angles, all in relation to each other and with 40 variations, that took a lot of programming! We were required to take the part from design stage to programming , setting and machining. The hard part didn't stop there, as the customer needed the parts in short runs, machines were being re-set every few hours with new variations. All of our staff picked up many new skills as the difficult project progressed. By introducing 24 hour shifts and investigation of new tools and tooling techniques, we were able to meet all of the customers requirements.

Over 20,000 components later and we are all very proud to have been a part of what is sure to become one of Auckland Down Town's most talked about structures.

For more on this project please visit our customers website here: http://www.thermosash.co.nz/